Debarking Stringy Bark….. Efficiently

Stringy cedar bark clogging a debarker ring to the extent of not being able to open the machine.

Efficiently Debarking Cedar & eucalyptus

Western red cedar and eucalyptus bark fibers primarily run longitudinally along the grain of the wood, creating unique challenges during processing. When debarking these wood species, these fibers form long, strong strands that frequently become stubbornly entangled with equipment such as log feeders, conveyors, and particularly the knife arms of debarkers. This persistent accumulation of bark fibers can result in unexpected production stoppages, causing significant slowdowns in sawmill operations and negatively impacting overall efficiency. This article offers practical recommendations and helpful suggestions designed to enhance the effectiveness and smoothness of cedar and eucalyptus debarking processes.

Suggestion #1 - Simple Quality Parts

Scoring Tips

Scoring tips can be very effective as a first line of defense to break up stringy bark before it travels further, getting hung up in the arm. Depending on the tip you’re running and the conditions you’re facing, a great solution is to add extra cutting pieces to make the most of the surface area of the tip to cut up the bark. Customers usually add 1-3 scoring marks per tip (based on debarking conditions) and install a tip every other spot to cut long bark into pieces 12 inches or smaller.

Cleaning Bars

What is the current condition of your cleaning bars? Are they worn down or washed away from extensive use? These cleaning bars are specifically designed to be securely mounted to your ring and designed to effectively knock out and slice through any bark buildup along the outside of your ring. Many mills, for improved performance, even add extra cleaning bars—such as repurposed old debarker tips—to provide additional assistance in preventing clogging and maintaining smooth operation.

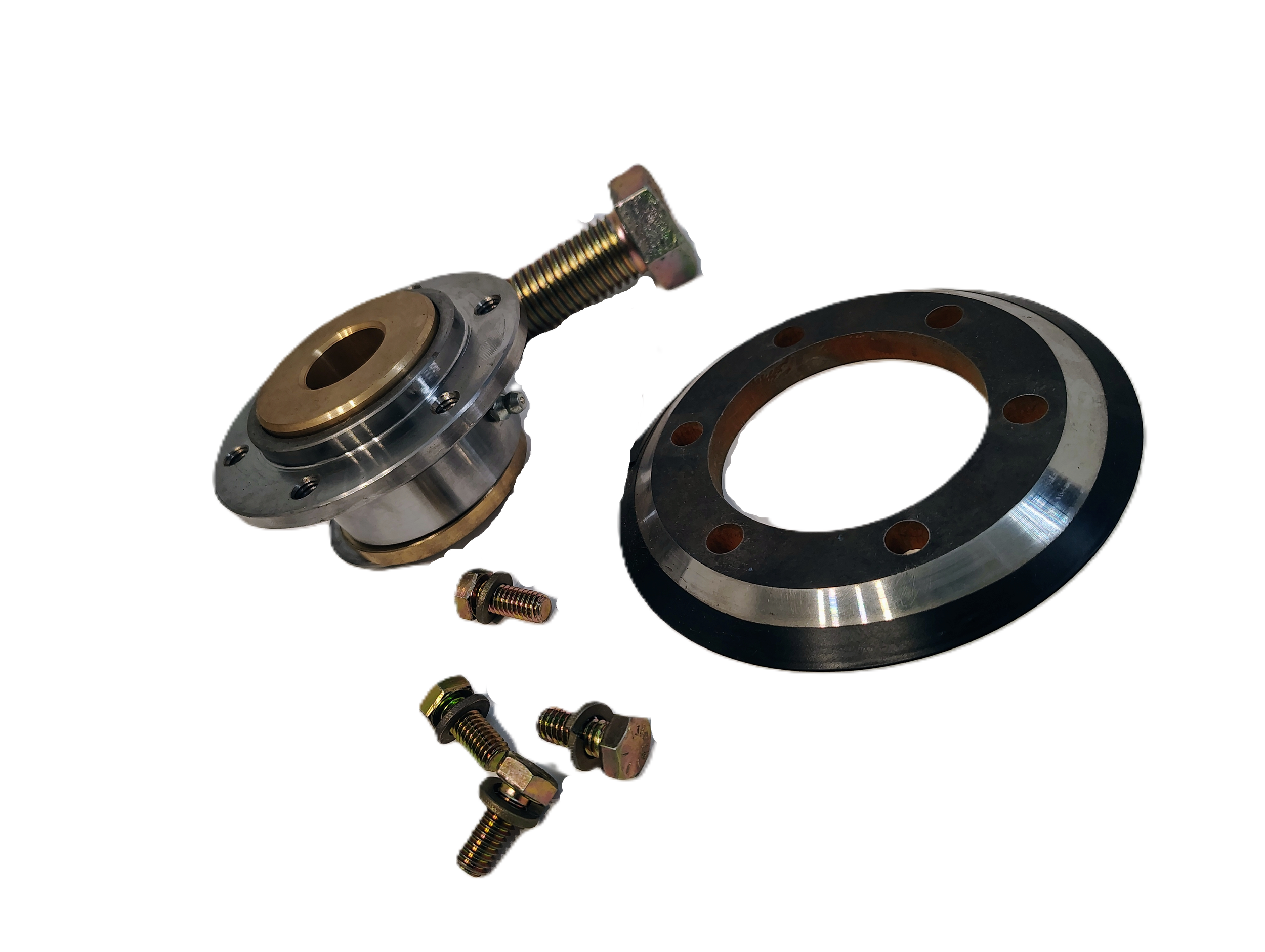

Pizza Cutter Arms

Pizza cutter arms are an excellent option if your machine has the capability to operate at a slower or variable speed. These arms are particularly effective when used on the first ring of dual ring machines, where they are specifically designed to slice the longitudinal bark into short sections prior to entering the second ring for actual debarking. To achieve optimal performance when running pizza cutter arms, it is essential to perform radius calculations and carefully control the feed speed. Proper adjustment of these factors ensures efficient and precise debarking results.

Sharp Pizza Cutter Discs

Make sure you have sharp pizza cutters installed on your machine at all times. Sawmills that handle stringy bark often find themselves needing to replace or grind their pizza cutters to a sharpness level comparable to a kitchen knife every 8-hour shift. Sharper knives consistently provide better cutting performance and improve overall efficiency.

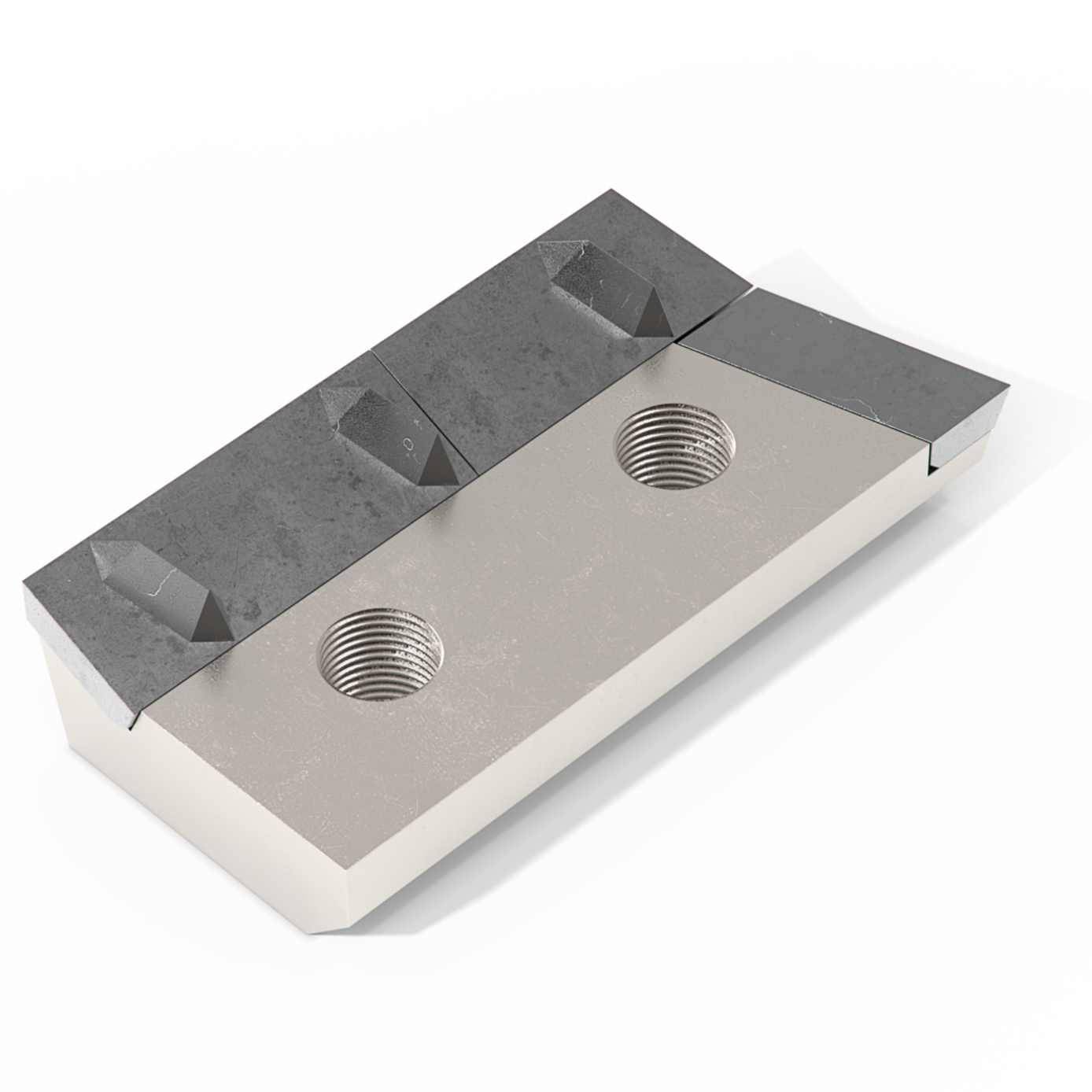

Carbide Cutting Edge Plate Arms

A sharp carbide lead edge has historically been used to facilitate easier arm openings during log entry and to help prevent excessive wear over time. In this particular instance, we have reversed the orientation of the carbide inserts and employed them as a cutting edge specifically designed to slice through long bark strands. This innovative approach can significantly reduce build-up on plate arm applications when compared to t-style arms, which are typically designed to deflect bark but may unintentionally contribute to increased bark accumulation within your ring.

Suggestion #2 - Operations

Log Feeding

Feeders and centering conveyors play a significant role in determining how much bark actually enters the debarking ring before the debarking operation. Auger or spiral feeders are generally more effective at removing a large quantity of loose bark before the wood reaches the centering conveyor. On the other hand, step feeders often carry most of the loose bark along to the centering conveyor, relying on it to fall off before the wood enters the debarker. The main objective in both cases is to minimize the amount of loose bark that reaches the debarking ring before actually debarking.

Debarker Feed Speeds & Operator Habits

Ensure your feed speed is set accordingly to the species, season and arm type. But a rule of thumb for stringy bark is slower, slower, slower! Reducing feed speeds significantly helps minimize clogging by allowing the machine additional time to effectively clear out and process loose bark.

Operators can also help prevent buildup by regularly cycling the debarker arms open and closed frequently in-between logs, knocking bark loose from the ring. Additionally, increasing the spacing and timing between feeding logs further aids in maintaining smooth operation and reducing the chances of blockages.

Preventive Cleaning

Scheduled ring cleanings are your best bet to ensure your operation is running efficiently and without unnecessary downtime. Many mills in our local area schedule a 15-minute shutdown after 2 hours of debarking stringy bark. Taking the time to shut down the equipment and thoroughly clean out the rings helps maintain optimal performance and prevents buildup that can otherwise halt production for hours.

Suggestion #3 - Monitoring

Temperature Monitoring

Watch your motor and ring temperatures closely. An increased temperature when running stringy bark is most likely due to a clogged ring of stringy bark. It is important to shut down your machine promptly and thoroughly clean out the blockage to prevent motor overheating and potential damage. If you run stringy bark wood species often it may be worth while to invest in thermal or mechanical monitoring system.

Sound Monitoring

Operators, supervisors, millwrights should always carefully listen to the debarker during operation. If you notice any unfamiliar or straining sounds, it is most likely caused by a clogged ring or feed rolls. Safely stop your machine as soon as possible and thoroughly investigate the source of the noise to prevent further damage. Your debarker will most likely require a clean out at this time.